The Baram Field, situated 30 km northwest of Lutong, Malaysia, is one of nine fields in the Baram Delta Operations (BDO) area offshore Miri, Sarawak, in approximately 18 to 60 meters of water depth. The field has its own set of challenges; long reservoirs and highly unconsolidated sand that require specific completion techniques to deliver sand-free production. There are also well economic challenges to ensure the cost of completion.

Turning Challenges into Opportunities

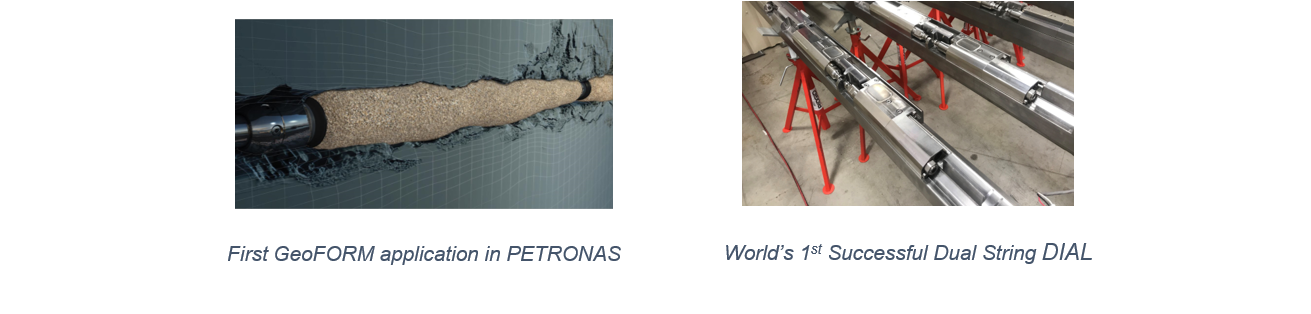

At PETRONAS, we believe in finding innovative solutions to every hurdle that comes our way. MPM led the way using a specific Technology Application and Replication (TAR) process to drive technology utilisation across all the different projects’ lifecycle. Keeping to its sand-free production strategy for Baram South field, In collaboration with industry technology providers, PETRONAS Carigali Sdn. Bhd. (PCSB) deployed GeoFORM and Enhanced Single Trip Multi Zone (ESTMZ™) sand management system as the technology solutions for the two (2) different wells.

High Impact, Cost Efficient

The GeoFORM system provides an open hole sand control method and a simpler, cost efficient operation by eliminating the need for complex gravel pack pumping operations. Deployed in Well 1, this Shaped Memory Polymer (SMP) technology has reduced the well cost by 26%. The ESTMZ™ system made it possible to develop fields with long reservoirs by optimising the number of days required to complete the wells. It was deployed in Well 2, where six (6) zones were fractured in a single trip, saving 23 rig operations days. These zones usually require sand control and conventional stack pack technique, which would take 33 days to complete a well. It also carries a higher risk of not achieving optimised sand control packing. This in return would prevent the well from achieving the minimum sand free rate (MSFR) during production. The ESTMZ™ not only shortened completion to 10 days due to its single trip operation, it also allowed Extension Pack fracking to be carried out for more efficient sand control. We have explored other technologies within the industry and GeoFORM, ESTMZ™ and DIAL were chosen as a fit-for-purpose solution.

The Future of Operations

Embracing the digital future, this project also witnessed the world’s first successful deployment of an intelligent dual string gas lift completion. The Digital Intelligent Artificial Lift (DIAL) system is composed of three (3) digitally controlled gas lift units per string and a sensing unit below the packer. It enables continuous production optimisation and monitoring, avoids gas robbing and significantly reduces OPEX and HSE risks by eliminating well interventions. This technology has successfully accelerated production for this field as a result of the teamwork with the technology provider.

The use of the completion technologies has unlocked significant value, optimised operations and enhanced reservoir performance. These have also helped overcome the economic challenges. By exploring modern and latest completion technologies, the project benefited through well cost and future OPEX reduction, quicker production monetisation and an improved sand management system. With the readily available MPM TAR process and guideline, various opportunities are available for operators and service providers to apply and replicate successful solutions.